|

|

|

| Truck Reviews (15215 Posts)

|

| Truck |

Review |

|

Weight

|

|

On 8/22/2005 GN

wrote in from

United States

(67.189.nnn.nnn)

OK: Sideloads put weight on the outside wheels

and bushings put weight on the inside. I think

it is possible that the sideloads are enough to

put as much or more weight on the outside wheels.

|

|

|

|

|

speedtrucks

|

|

On 8/22/2005

jawes

wrote in from

Sweden

(217.211.nnn.nnn)

Hi..what trucks for downhill do you recommend?

|

|

|

|

|

Been there, done that

|

|

On 8/22/2005

Chris Chaput

wrote in from

United States

(66.116.nnn.nnn)

Once upon a time, I thought that it would be tricky, but fun, to ride a board that didn't didn't have cushions in the trucks. I took the cushions out of my PVDs, which were mounted on a speedboard. It was more than just tricky - it was damn near impossible to stay upright for any length of time, and completely impossible to ride as a true skateboard. The board would just flop over onto its side, because there is nothing to prevent it from doing so. Without cushions or turn limiters, it just flops until the truck bottoms out on itself. The wheels do turn when it flops, but there is nothing in between "flat" and "flopped".

In short, it is completely useless as a skateboard, and it doesn't really steer - it just flops. As such, I don't think think of it as a lean-steer vehicle. It doesn't lean (it flops), it doesn't steer (you can't control it), and it's not a vehicle (you can't ride it). If somehow there was a moment where a rider managed to stay "frozen" while turning in a ever decreasing spiral, then who knows, maybe the outside wheels could have as much (or more) weight on them. But what does that have to do with skateboarding?

|

|

|

|

|

Still Weighting...

|

|

On 8/21/2005

Geezer-X

wrote in from

United States

(151.200.nnn.nnn)

Thanks Mr. Z.

I had an excellent truck tech discussion at The Farm race w/ Pierre Gravel. I dig your hangers.

|

|

|

|

|

where's the weight?

|

|

On 8/21/2005

jimz

wrote in from

Canada

(24.71.nnn.nnn)

"If one were to replace their bushings with spherical bearings, so there was no elastomer opposing the riders lean steer input, then the wheels would all remain loaded, for the most part, equally. Add the side load generated in a turn, and now the outside wheels are more loaded. "

Great way to explain it. I remember this was a hot topic awhile ago.

|

|

|

|

|

Ahhh, but...

|

|

On 8/21/2005

Geezer-X

wrote in from

United States

(68.239.nnn.nnn)

What about the friction circle?

This has all been visited ad nauseum, but surely someone will start illustrating thrust vectors and friction circles, etc.

Chris' statement is true, but simplified. If one were to replace their bushings with spherical bearings, so there was no elastomer opposing the riders lean steer input, then the wheels would all remain loaded, for the most part, equally. Add the side load generated in a turn, and now the outside wheels are more loaded.

My point is that the technology works fine, but not with skateboard wheels. All road race cars have negative camber. Dirt oval cars have negative on the outside of the car, positive on the inside.

Slalom wheels are "square" and have well supported lips to exploit all the possible grip when they're aligned with one another, That's why the straighter and stiffer your rear truck, the better and more predictable grip you have.

Angling both wheels relative to the racing surface is the same as 2 bent axles. It will provide the illusion of grip, but you're on the edges, not the body of the contact patch, so the breakaway will not be as predictable.

A combination of grip and predictability is what makes for a setup which makes one confident in ones grip.

And that's what you need to attack.

|

|

|

|

|

platform/truck alignment?

|

|

On 8/20/2005 AJ

wrote in from

Canada

(66.131.nnn.nnn)

Whats up with lowered decks like some kebbek boards that

have a platform levelled to the center of the pivoting point in

a truck? Is this better than other lowered boards like the DH

Race or the Evo, whom's platforms go far lower , even below the axles?

|

|

|

|

|

The Outside Wheels

|

|

On 8/20/2005

Chris Chaput

wrote in from

United States

(66.116.nnn.nnn)

One way that I know that MY outside wheels have less weight on them in a turn is because if they had more weight on them, I'd be steering in the opposite direction. Skateboards are lean-steer vehicles, unlike cars that have steering wheels and linkage. There HAS to be more weight on the inside wheels of a turn or the board won't turn in that direction.

Take this simple test. Ride in a parallel stance and steer to the left. You had to put weight on the left side of the board (and wheels) to accomplish this. If you put more and more weight on the left, the right wheels will come off the ground completely, giving you a pretty strong indication that there is more weight on the wheels that have remained in contact with the ground - the inside wheels.

If you doubt this, then try the following. While turning left in a parallel stance, take your left foot off of the board and see what happens. There may be a brief moment where the outside wheels had more weight on them, followed by an immediate crash to the pavement.

If you had a skateboard with trucks that had zero steering geometry, it would lean, but not turn. But if you took that same board, added a steering wheel (or handlebars) on a pole that could pivot the front trucks, then the forces would tend to put weight on the outside wheels. But guess what? That's not a skateboard. It's a four wheeled scooter.

I believe that if you attempt to put more weight on the outside wheels, it won't give you more traction, it will give you less steering. Perhaps if the truck steered the right amount in the first place, you'd have the traction without trying to weight the outside wheels. I think that the better way to get more traction lies in getting more urethane on the ground in the turn. Considering how much axles and hangers flex under a load, perhaps canting the unloaded axles a bit would put them flat in a turn. It's hard to say how much roll-speed would be lost in the straights, and what the best wheel designs would be for that type of system.

|

|

|

|

|

Wheel concentricity

|

|

On 8/20/2005

Geezer-X

wrote in from

United States

(68.239.nnn.nnn)

With the dual trailing arm configuration, when the two arms move relative to one another, this being the supposed advantage of this configuration, the net physical result is that the contact patch of both wheels is not longer evenly weighted from inside to outside. The way that a skateboard turning with this type of truck would weight the contact patches would be effectively loading the contact patches toward the inside of the turn.

Skateboard wheels are "square". They are not especially deformable, and as such to acheive the largest possible contact patch, and more importantly, the most evenly weighted contact patch, it is necessary to hold the most rigid possible concentric relationship between the wheels.

|

|

|

|

|

My Question????????

|

|

On 8/20/2005 Gear Nerd

wrote in from

United States

(67.189.nnn.nnn)

How do we know that the outside wheel has less weight

in a high G turn? The riders weight will be at and angle,

45 deg and this would line up towards the outside wheel.

This is much different than standing still and leaning

onto two wheels.

A drop deck seems like it may load the inside wheels more

but a slalom deck with risers should be more evenly

loaded between the inside and outside wheels.

|

|

|

|

|

Controverial Radikal and 14 degrees of Pos Wedge Hornets Nest

|

|

On 8/20/2005 Pauliwog

wrote in from

United States

(64.5.nnn.nnn)

I don't want to start another CONTROVRSY, but a good 14 degree pos wedged Radikal with a trimmed clear bottom bushing and a trimmed yellow stim up front with an 8mm RT-S dewedged at 12 degrees or better yet, a 100mm 8mm MMW Seismic with the 45degree baseplate with no wedging in back with an 18" wb on a concave wood plank does some impressive 4ft (and less) center-to-center English sorta Tight Slalom. Ok, so that's pretty much it, take it or leave it, That's all I have to say for now, unless that is that I come up with more to say at some point later in time, if that the case then of course I'll present my statements here, just incase anyone wants to know. Really, I will. Ok, so that's about it I guess. Sincerely -P

|

|

|

|

|

Traction Lab

|

|

On 8/19/2005

jimz

wrote in from

Canada

(24.71.nnn.nnn)

Square profile wheels gotta stay concentric to optimize speed and grip. I like what's goin on over there tho!

|

|

|

|

|

traction lab v 1.0

|

|

On 8/19/2005 ur13

wrote in from

(69.121.nnn.nnn)

Seismics in the rear do the same thing the traction lab is trying to do (probably to a lesser degree though). The outside spring in actually pushing the outerwheel down to the surface, less so the more the truck is turned (and weight of the springs), but it is doing it. I think this is why alot of the swiss guys on spongey boards with little torsional rigidity always used a Seismic in the rear...the added traction.

|

|

|

|

|

I question your question

|

|

On 8/19/2005

WesE

wrote in from

United States

(4.249.nnn.nnn)

Gear Nerd (please choose a different name, I don't want to sound like I'm ridiculing you),

Even if what you say would happen in a real world turn was true (it's not), the truck would still have the advantage that Billbee says it has. The less-weighted wheel holds more contact with the pavement than it would on a regular, fixed-hanger truck.

|

|

|

|

|

Traction Lab

|

|

On 8/19/2005 gear nerd

wrote in from

United States

(67.189.nnn.nnn)

"The idea here is to actually have a contact patch on the "unweighted wheel" through a turn. Simple test...put a dollar bill under the heel side rear wheel,standing still of course, lean toe side as far as you can, have someone tug on the dollar bill...Have not found a truck yet to grab the bill."

I don't think this test is valid. In a real world turn with centrifical

force weight will transfer to the outside wheel. More with higher risers

and less with a drop deck. I am not saying you truck does not work but

question the explanation of why it works.

|

|

|

|

|

re billbee

|

|

On 8/18/2005 herbn

wrote in from

United States

(152.163.nnn.nnn)

not say'n they don't work BUT that dollar bill test,,,"not moving" is very key downward pressure would come from moving your weight through the corner. The torsion bar type of suspension would seem to have a bit of an advantage, maybe,apparently it does,well third place(?) who knows, the small print always says "your results may vary" they definitely look like someone (similar to me) who thinks that skateboards are just to damn easy to bolt together and is looking for a challenge. That dollar test is just a bit slanted.

|

|

|

|

|

Dangit

|

|

On 8/18/2005 FL

wrote in from

United States

(65.249.nnn.nnn)

The previous post should have said "lower the bushing receiver on the front truck" ...FL

|

|

|

|

|

Uh Trucks , I Hope

|

|

On 8/18/2005

FL

wrote in from

United States

(65.249.nnn.nnn)

If you are pulling most of the steering out of the rear trucks for high speed cornering , and you find your turn-in a bit slow , cut off the bushing receiver on the axle hanger and move it closer to the ground . I had a local race car welder reweld the receiver app. 1/4" lower . A longer kingpin and possibly a spacer for the top bushing and you should be good to go . Do not use this on unfamiliar track , as your ground clearance may be compromised . But you probably knew that already ...FL

|

|

|

|

|

Traction Lab trucks at Walmart?

|

|

On 8/18/2005 EBasil

wrote in from

United States

(207.200.nnn.nnn)

What do those Traction Lab trucks cost, each, and where do you get them from? They have the look of individual craftsmanship...

|

|

|

|

|

Adjust

|

|

On 8/17/2005 Jackie Economaki

wrote in from

United States

(207.114.nnn.nnn)

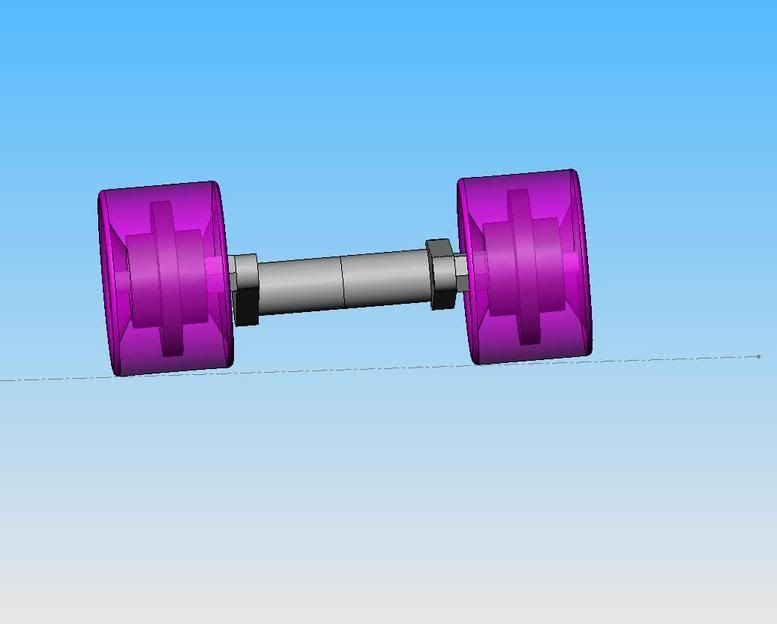

If you look close you will see that the pivot is an allen head screw, back it out and you can remove the hanger for easy bushing replacement. No need to remove the kingpin.

A quick turn of the set screw and you can adjust the torsion bar load.

|

|

|

|

|

truck adj's

|

|

On 8/17/2005 bara

wrote in from

United States

(204.78.nnn.nnn)

snug up the bushings and do the fine tuning with that tension fitting on the springsteel?

|

|

|

|

|

Traction Lab

|

|

On 8/17/2005

Jack

wrote in from

United States

(207.114.nnn.nnn)

Actually the design is very simple. Adjusments are easy to make.

|

|

|

|

|

Traction Lab

|

|

On 8/16/2005 Bara

wrote in from

United States

(68.61.nnn.nnn)

OK....next time somebody tells me the PVD is too complex, i'm showing 'em those pix...

|

|

|

|

|

Alfa Romeo

|

|

On 8/16/2005

T.O.

wrote in from

United States

(12.148.nnn.nnn)

That Traction Lab is definitly a cool design for a rear truck...Thanks for the Pics!

Now all it needs is something like a De Dion setup...

|

|

|

|

|

Geez/ Traction Lab

|

|

On 8/16/2005

billbee

wrote in from

United States

(66.214.nnn.nnn)

The idea here is to actually have a contact patch on the "unweighted wheel" through a turn. Simple test...put a dollar bill under the heel side rear wheel,standing still of course, lean toe side as far as you can, have someone tug on the dollar bill...Have not found a truck yet to grab the bill. The truck in the Traction Lab post below won't let go. We have been running harder duro wheels w/o traction loss. PD was the only racer at Hood River GS on Avila diameter wheels(to the best of our observation) Wheel wear/coning seems to be significantly reduced. This thing works. While not the greatest tight slalon truck because of rebound lag, this puppy growls through big GS offsets. The rear trailing torsion arm concept has been utilized by VW and Porsche since the beginning. As far as contact patch concentricity goes...huh

Jack will have one at Breckenridge,check it out.

|

|

|

|

|